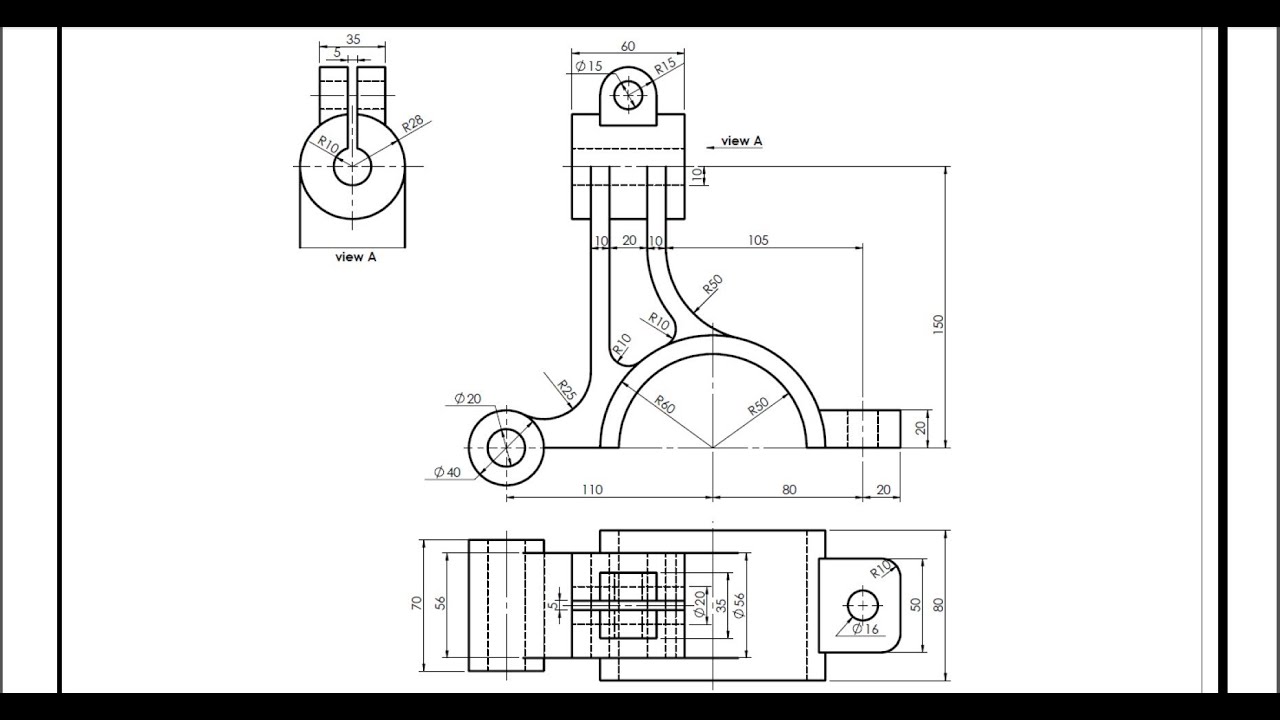

Operation-based features are not sketch-based, and include features such fillets, chamfers, shells, applying draft to the faces of a part, etc.īuilding a model in SolidWorks usually starts with a 2D sketch (although 3D sketches are available for power users). This shape is then extruded or cut to add or remove material from the part. Shape-based features typically begin with a 2D or 3D sketch of shapes such as bosses, holes, slots, etc. They are the shapes and operations that construct the part. SolidWorks allows you to specify that the hole is a feature on the top surface, and will then honor your design intent no matter what the height you later gave to the can.įeatures refer to the building blocks of the part.

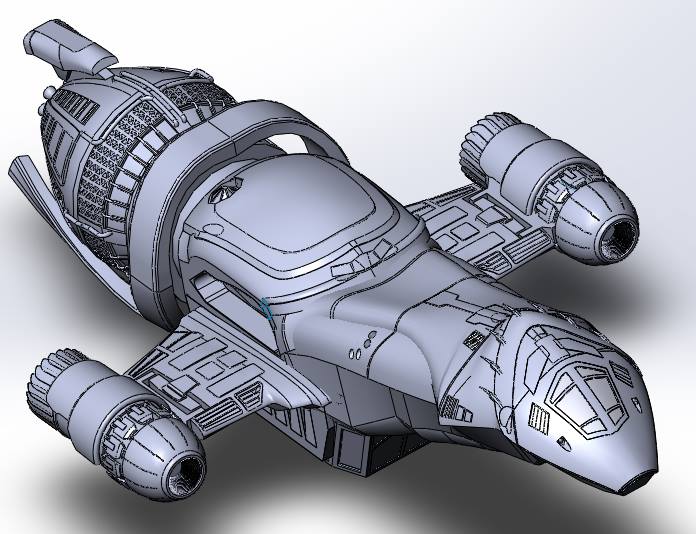

For example, you would want the hole at the top of a beverage can to stay at the top surface, regardless of the height or size of the can. Numeric parameters can be associated with each other through the use of relations, which allows them to capture design intent.ĭesign intent is how the creator of the part wants it to respond to changes and updates. Parameters can be either numeric parameters, such as line lengths or circle diameters, or geometric parameters, such as tangent, parallel, concentric, horizontal or vertical, etc. Parameters refer to constraints whose values determine the shape or geometry of the model or assembly. SolidWorksis a parasolid-based solid modeler, and utilizes a parametric feature-based approach to create models and assemblies. Screen shot captured from a SolidWorks top-down design approach.

0 kommentar(er)

0 kommentar(er)